29th June, 2021

Standard Operating Procedures are the key to unlocking a business that can truly scale without threat to productivity as a result of a lack of uniformity.

There’s a lot that goes into establishing smooth business operations that can produce the desired output. Fortunately, there are various resources, strategies, and techniques available these days to help businesses thrive.

A typical example of such a “technique” is the standard operating procedure document. From training new employees to establishing work policies and procedures, Standard Operating Procedures (SOPs) help companies keep everyone on the same page and ensure that employees understand the details needed for completing their assigned tasks.

If you’re wondering if SOPs are something you should consider doing, this article will provide you with important context for making that decision.

A standard operating procedure (SOP) is a document that contains detailed instructions to guide the employees in an organisation while executing routine or repetitive tasks and activities.

Companies develop and use SOPs as an integral part of their quality management system because it provides individuals with the information to perform every job consistently every time, thereby helping to guarantee the quality and integrity of the end product or service.

The traditional idea of an SOP is a written document that outlines best practices for a process and lists them step-by-step. But, they can come in any of the following formats:

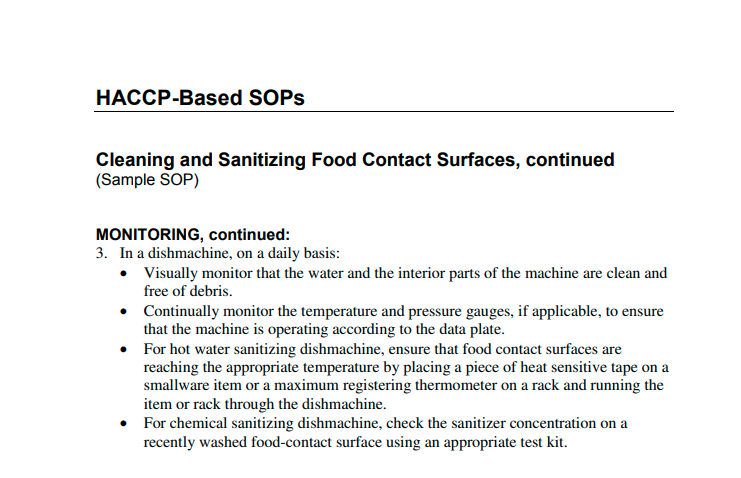

This type of SOP consists of simple instructions describing every step employees need to follow to complete assigned tasks.

Step-by-step SOPs are ideal for procedures with easy-to-follow instructions that can be explained in simple sentences. But this type of SOP would be insufficient for processes that require additional information or that may have unpredictable outcomes.

For instance, a set of instructions telling cleaners how to tidy up a meeting room can follow the step-by-step format.

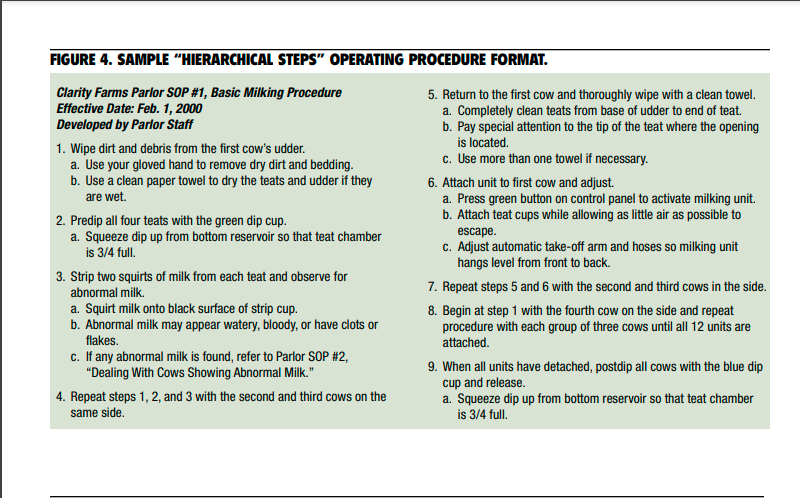

At a glance, this SOP is similar to the step-by-step list SOP but it’s a better choice for companies with complex procedures where each step requires further information to proceed.

Therefore, while a step-by-step SOP may simply list steps 1, 2, and 3, a hierarchical SOP would further include steps 1a and 1b; 2a and 2b, then 3a and 3b.

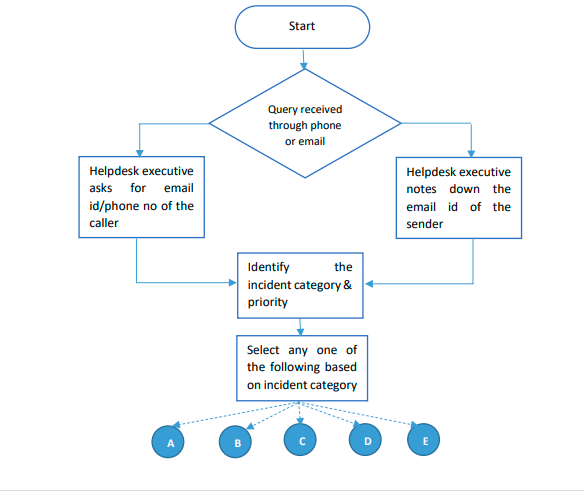

Flowchart SOPs present instructions and information visually. The entire process is broken down into steps that are described in diagrams.

Each diagram (step) is placed in sequential order leading to the next step and so on.

Businesses use flowchart SOPs when their processes are too complex to be described in simple sentences and when there could be multiple outcomes possible at specific points throughout the process.

Now that we have a better idea about SOPs, let’s look at a few pointers to help you decide if your business needs this level of documentation or not. We’ll start by asking – which kind of companies use SOPs the most?

In general, most businesses can benefit from having SOPs. There are always some business processes that should be standardised as you scale your business operations.

Businesses tend to use SOPs for the following reasons:

Considering the above, manufacturing businesses, the military, the aviation industry, food and beverage establishments, and the pharmaceutical industry (to mention a few) use SOPs the most.

In fact, regulatory bodies like the USA’s Food and Drug Administration (FDA) have specific SOP guidelines for pharmaceutical companies. In addition, SOP documentation is a usual requirement for organisations that want ISO certification.

On the other hand, if your business fits the following model, then you don’t necessarily need to write SOPs:

If you decide that SOPs are a fit for your business, the next step is to consider your options for handling the SOP creation process.

Depending on how large and complex your operations are, you may choose to start creating SOPs from scratch using an in-house team, or you could outsource this as a project to an SOP consultancy company. Here are a few things that an outsourced SOP consultancy service will do for you:

Furthermore, you could also opt for one of the many SOP software available on the market today. These solutions are usually cloud-based, and they offer a wide range of features. Some popular brands include Process Street, systemHub and SweetProcess.

Those that want to handle this in-house, here are five tips to guide you through the creation process.

Creating SOPs for the first time will test everybody on your team. Prepare to encounter unexpected frustrations such as unwilling staff, missing documentation, and other unforeseen challenges.

To help make the process easier, get employee support as early as possible and ensure that everyone is on the same page about how the SOPs will improve everybody’s jobs.

Next, select the people in your organisation to lead this project by asking questions like: who are the best people to write this? Do they know what the process entails and where things could go wrong? This team would be responsible for seeing this project through to completion.

By holding specific people accountable for the success of the SOPs, you improve the chances of meeting deadlines and major milestones.

The first thing your team will need to do is to decide which processes they are writing SOPs for — the selected processes will mainly be centered around the company’s mission-critical jobs and activities, as well as those that offer significant productivity gains by being standardised.

Once that’s done, they can proceed to start gathering relevant information (through manuals, staff interviews, existing guidelines…). This information will serve as a good foundation for your SOPs. Old records often provide valuable insights into your existing processes, best practices, and any limitations or weaknesses in your system.

Your SOPs will likely require several reviews before they are ready for distribution.

While testing, it’s important to involve employees at different levels of experience to review the procedures.

Also, at some point, use staff with little knowledge of the process to test the SOP. Because sometimes, staff with prior knowledge of the procedure may rely on their knowledge rather than the new SOP in front of them, thereby defeating the purpose.

Note any issues the testers encountered, address them, and make the necessary improvements.

Once approved, don’t wait for perfection. Start implementing the SOP. This will usually kick off with a series of formal training sessions for the affected staff. Remember to record evidence of this training.

Also, it’s good practise to check that your SOPs remain current. When updates are due, get them done, re-approve the new SOPs, and withdraw the outdated ones. Failure to do this can negatively impact the safety and productivity of your team, especially in the industrial setting.

Nobody wants to be burdened with tons of documentation and processes, we get that.

But, no matter the improvements and innovations achieved in your business, if you can’t document it or reproduce it to pass on to different staff to use, it has no business value.

Doing business without any push for standardisation can be a costly mistake that disrupts your business growth.